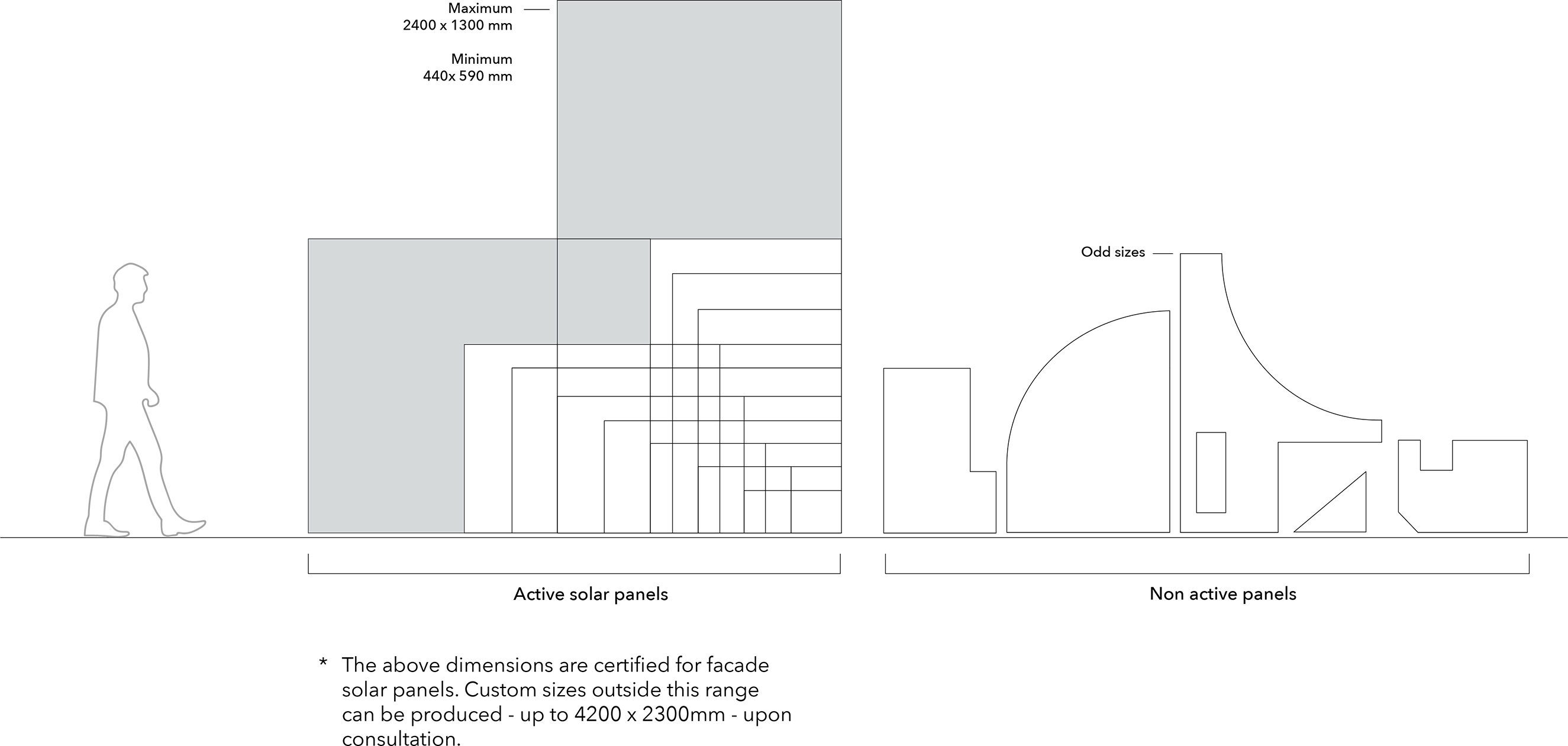

Ideal dimensions of solar panels for facades

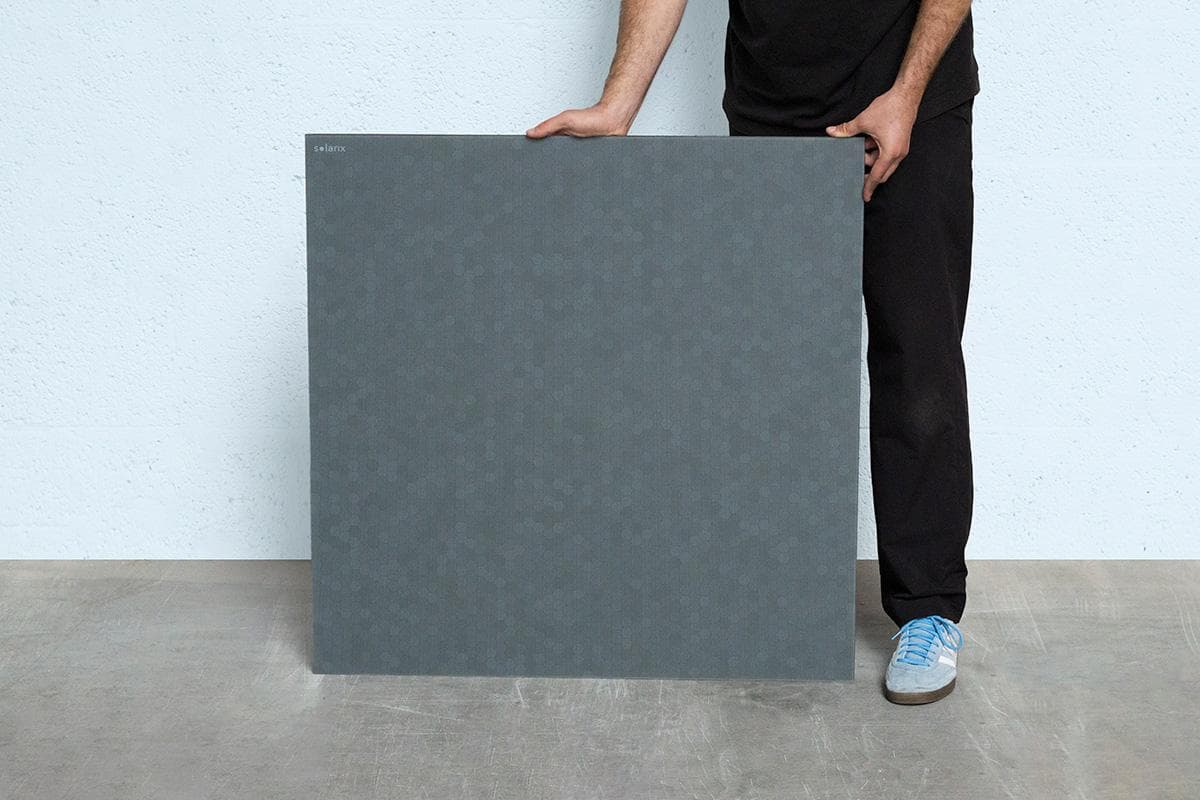

At Solarix, we tailor the dimensions of our solar panels precisely to the design of each project. For every facade, we seek the ideal balance between solar panel yield, aesthetics, and efficiency in production and installation. By making smart use of dimensions and the variation in panel sizes, we achieve gains in design freedom, cost, time, and maximise solar energy generation.

Customization for optimal integration of solar panels in leading architecture or sustainable redevelopment

What is the optimal solar cell integration for custom solar facades?

Solarix solar panels for the facade are glass/glass panels between which the solar cells are encapsulated. The size and quantity of the solar cells determines the optimal dimensions of a panel and the final amount of energy generated. For each project we look at what the desired dimensions of the solar panels can be. The Solarix engineering team looks for optimal coverage of the cells in the panels and coverage over the entire facade. Sometimes it happens that the desired panel size deviates from the solar cell coverage ratio and 'dead space' is created, which leads to a lower power density (Wp/m²) of the entire facade.

A few rules for sizing custom panels:

The optimal size for a facade panel is between 0.5 and 2 m².

Dimensions larger or smaller than this are generally more expensive due to the complexity of production, installation (weight), and transport.

For panels larger than 2 m², we recommend discussing the design in advance with our engineering team.

The same applies to panels smaller than 0.5 m² — we advise consulting our engineering team beforehand to assess whether an active solar panel or a non-active dummy panel is the better choice.

Our engineering team is also happy to support you in achieving the optimal integration of solar panels, managing shading on the facade, and developing the electrical plan — all of which significantly influence the final panel dimensions.

What does shade mean for facade solar panels and their dimensions?

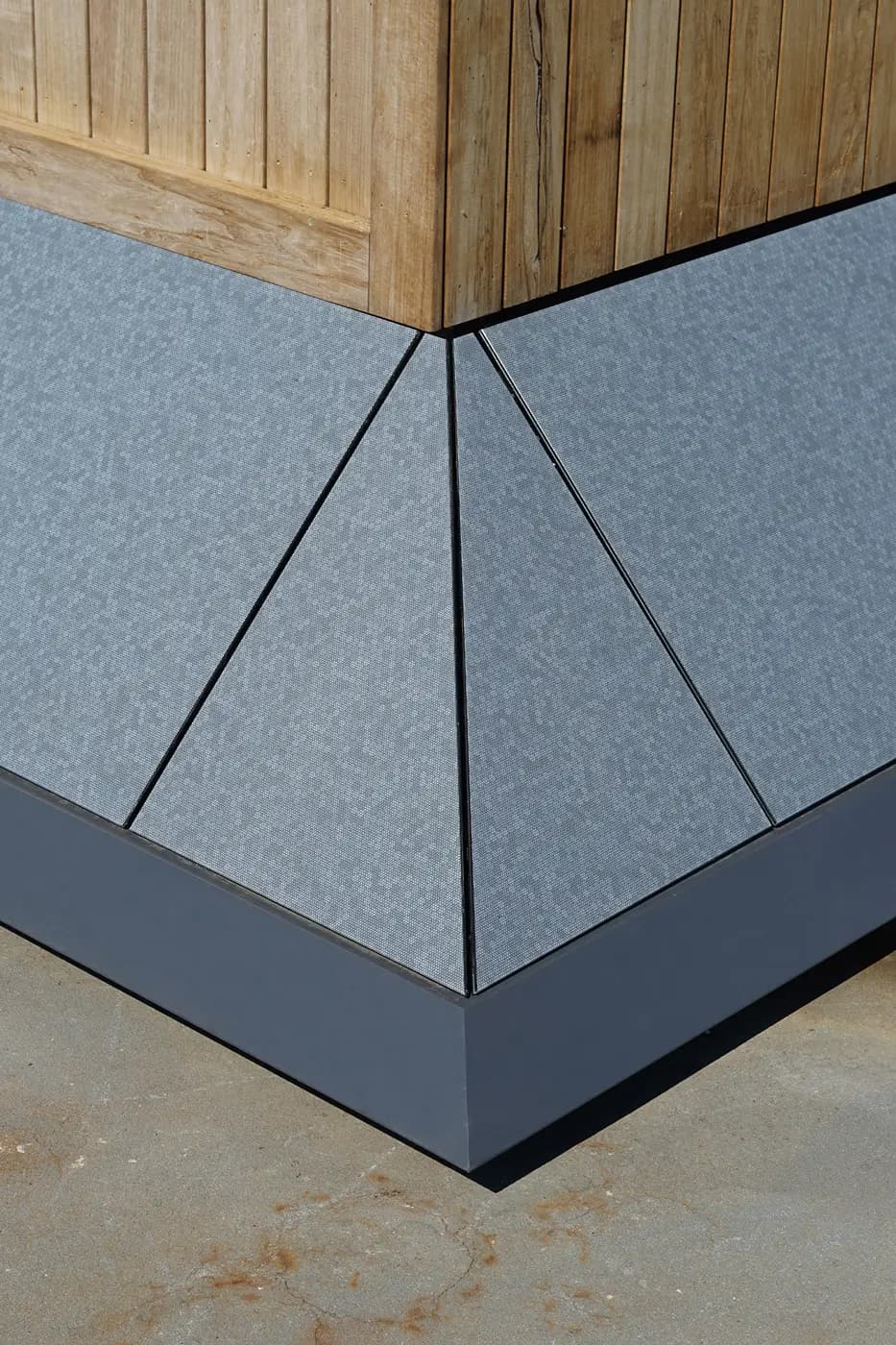

In some projects there is shadow. Sometimes in such a way that part of the solar panel is in the shade and another part is not. This can have major negative consequences for the yields of the panels. For optimal performance of the panels, a facade is designed that does not allow shadows to fall on the solar panels. If this is the case, Solarix can provide input at an early stage about the electrical design of the solar panels and the overall design of the building and facades. Playing with dimensions and additional non-active 'Dummy panels' can contribute to an attractive facade design.

What influence does the electrical plan of the facade have on the dimensions?

Finally, panel size and electrical configuration together determine the electrical parameters of the solar panel. And the latter has an effect on the choice of inverters, micro-inverters or optimizers. The electric solar panel parameters must match the characteristics of these devices and the totality of the facade.

Dummy panels

For optimal connection of solar panels in the facade design, non-active fitting pieces can be used for small sizes, in places with permanent shade and for few repeating sizes. These dummy panels are aesthetically similar to active panels, but do not contain solar cells and are therefore financially more advantageous.

Non-rectangular panels as fitting pieces are possible and are offered as dummy panels.

The Solarix team contributes to facade engineering and optimizations

Want to get started with Solarix standard panels? Immediately download all information and draw models

Design tools (2D & 3D)

Which dimensions fit perfectly in your facade?

Frequently asked questions about solar facades

To provide you insight into the application possibilites of our solar-facadepanels, we would like to invite you for an intake so we can discuss your project(s). We are happy to have you in our showroom in Weesp near Amsterdam, or we schedule an online appointment. When applicable, we can make a SolarCheck for the project that will give you insight into the potential energy generation of the facades and the business case.

The next step is a SolarScan. This is paid preliminary engineering in which we investigate in detail how our panels should be integrated into the facade. This includes detailing, panel layouts, research into optimalisation options, extensive insolation study incl. shadowing, and a proposal for the mounting system.

Please contact our accountmanagers or call +31(0)20-2440641 to schedule an intake.

A Solarix solar facade is a ventilated system and can be integrated into almost all facades. In most cases, this is possible with the Solarix mounting system, such as for a facade builder of timber frame construction or steel, sandwich panels, concrete and brick. The solar facade panels can also be incorporated into curtain walls, for example, in that case without the Solarix mounting system. However, these types of applications require the necessary engineering and development.

It is advised to mount horizontal strips. Work from the bottom up. However, this is not necessary. Our panels can also be mounted in an alternative order. Tough, it is important that the panels are connected by a certified electrical installer. For more details, you can find our assembly manual here.